RZOLV Technologies Successfully Completes Bulk-Scale Vat Leach Test at Operating Gold Mine, Advancing Commercial Validation of RZOLV Non-Cyanide Gold Extraction

Rzolv Technologies Inc. (TSXV: RZL) (the ‘Company’ or ‘RZOLV’) today reported the results of a bulk-scale vat leach metallurgical test conducted at an independent, operating gold mine in Arizona, marking a significant milestone in the commercial validation of the Company’s proprietary non-cyanide gold leaching technology.

The program represents RZOLV’s most advanced scale-up validation to date, moving beyond laboratory conditions to evaluate metallurgical performance, solution chemistry, reagent stability, hydrodynamics, and operability under representative operating conditions and at meaningful tonnage.

Bulk-Scale Test Highlights:

- 73.5 tonnes of low-grade oxidized gold mineralization were processed at an operating mine in Arizona.

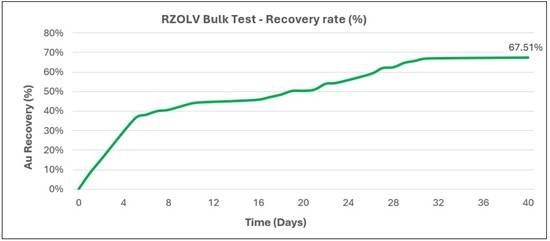

- The test achieved an overall gold recovery of 67.51% over 40 days under the specific conditions evaluated, with recoveries comparable to laboratory-scale reference tests conducted using 1,000 ppm sodium cyanide.

- The RZOLV

leach solution demonstrated predictable scale-up behavior, with metallurgical performance consistent with prior laboratory-scale test work.

leach solution demonstrated predictable scale-up behavior, with metallurgical performance consistent with prior laboratory-scale test work.

- Solution chemistry remained stable throughout the test, maintaining targeted pH and oxidation-reduction potential (ORP) ranges, with no evidence of instability, precipitation, compaction, or channeling.

- Leached residues exhibited low residual gold content and maintained favorable permeability characteristics throughout the test period.

- Effective gold adsorption onto carbon was achieved, confirming compatibility with conventional carbon adsorption and electrowinning circuits.

- Doré production and final weight were consistent with calculated carbon loadings and overall metallurgical accounting.

CEO Commentary

Duane Nelson, President and CEO of Rzolv Technologies Inc., commented: ‘This bulk-scale vat leach test represents an important inflection point for RZOLV. Processing more than 73 tonnes of ore at an operating mine allowed us to validate not only metallurgical recovery, but solution stability, hydrodynamics, reagent behavior, and carbon performance under real-world conditions.’

‘The predictable scale-up behavior observed in this program provides strong technical support for further commercial evaluation and reinforces our confidence that RZOLV can serve as a viable non-cyanide alternative for certain gold processing applications.’

Bulk-Scale Test Confirms Scalable Metallurgical Performance

The bulk test processed 73.55 tonnes of low-grade gold oxide mineralization hosted in gneissic and granitic lithologies. Run-of-mine material was crushed and screened to minus ½ inch (12.5 mm) plus 18 mesh (1 mm) and treated in a lined vat leach configuration with controlled solution circulation, collection, and carbon adsorption.

Under the specific test conditions evaluated, the 40-day bulk-scale vat leach achieved an overall calculated gold recovery of 67.51%. These results are consistent with multiple laboratory-scale leach tests conducted on the same test material, supporting the representativeness of the bulk-scale metallurgical performance.

Gold dissolution and recovery kinetics observed at bulk scale were consistent with prior laboratory-scale RZOLV and cyanide leach studies, indicating predictable scale-up behavior.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11597/279454_rzolv1.jpg

Mass Balance Closure and Operability Confirm Process Integrity

From an operational standpoint, the test confirmed:

- Stable and predictable reagent consumption

- Sustained solution chemistry within targeted pH and ORP ranges

- Effective gold adsorption onto conventional activated carbon

- Compatibility with standard pumps, liners, instrumentation, and control systems

No evidence of solution instability, deleterious precipitation, compaction, or channeling was observed at the tested crush size. Irrigation flux, drainage behavior, and hydrodynamics remained stable throughout the test period.

| Stream | Mass (t) | Au Grade | Contained Au (g) | Au Distribution (%) |

| Calculated Head (Feed) | 73.56 | 1.373 g/t Au | 100.98 | 100.00% |

| Pregnant/Process Solution (final) | — | 1.12 PPM Au | 68.788 | 67.51% |

| Final Tailings | 73.56 | 0.450 g/t Au | 33.100 | 32.49% |

| Mass Balance Closure | — | — | 100.98 | 100.00% |

Comparison to Cyanide and Prior Test Work

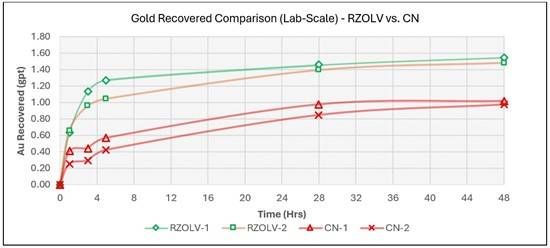

Parallel laboratory-scale bottle-roll testing was conducted using RZOLV and sodium cyanide on the representative oxide material (ground to <500 microns) to benchmark leach kinetics, dissolved gold tenors, and overall metallurgical response under controlled conditions. The laboratory results demonstrate that RZOLV

and sodium cyanide on the representative oxide material (ground to <500 microns) to benchmark leach kinetics, dissolved gold tenors, and overall metallurgical response under controlled conditions. The laboratory results demonstrate that RZOLV exhibits gold dissolution behavior and recovery profiles comparable to cyanide, and in some tests, exceeding cyanide under identical laboratory conditions.

exhibits gold dissolution behavior and recovery profiles comparable to cyanide, and in some tests, exceeding cyanide under identical laboratory conditions.

Under the specific laboratory test conditions applied, RZOLV achieved dissolved gold concentrations ranging from 1.48 to 1.55 gpt Au in solution over a 48-hour leach cycle, compared to 0.98 to 1.02 gpt Au achieved using a reference solution containing 1,000 ppm sodium, consistent with typical laboratory benchmarking concentrations’. Early-time leach kinetics for RZOLV

achieved dissolved gold concentrations ranging from 1.48 to 1.55 gpt Au in solution over a 48-hour leach cycle, compared to 0.98 to 1.02 gpt Au achieved using a reference solution containing 1,000 ppm sodium, consistent with typical laboratory benchmarking concentrations’. Early-time leach kinetics for RZOLV were also observed to be equal to or faster than cyanide, with materially higher dissolved gold tenors achieved within the first 5 hours of leaching.

were also observed to be equal to or faster than cyanide, with materially higher dissolved gold tenors achieved within the first 5 hours of leaching.

These laboratory-scale results are consistent with, and closely mirror, the pregnant solution gold tenors (~1.12 ppm Au) observed during the bulk-scale vat leach program, providing strong validation that RZOLV performance scales predictably from bottle-roll testing to bulk processing under representative operating conditions. The alignment between laboratory and bulk-scale data reinforces management’s confidence in the technical robustness, scalability, and commercial relevance of RZOLV

performance scales predictably from bottle-roll testing to bulk processing under representative operating conditions. The alignment between laboratory and bulk-scale data reinforces management’s confidence in the technical robustness, scalability, and commercial relevance of RZOLV as a non-cyanide gold leaching technology.

as a non-cyanide gold leaching technology.

| Leach Solution | Recoveries (GPT) | ||||

| 1 hr | 3 hrs | 5 hrs | 28 hrs | 48 hrs | |

RZOLV Leaching Solution (Test 1) Leaching Solution (Test 1) |

0.64 | 1.14 | 1.27 | 1.46 | 1.55 |

RZOLV Leaching Solution (Test 2) Leaching Solution (Test 2) |

0.65 | 0.96 | 1.05 | 1.4 | 1.48 |

| Sodium Cyanide Reference Solution (Test 1) | 0.41 | 0.45 | 0.57 | 0.98 | 1.02 |

| Sodium Cyanide Reference Solution (Test 2) | 0.26 | 0.3 | 0.43 | 0.85 | 0.98 |

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11597/279454_rzolv2.jpg

Key Technical Observations

- Comparable leach kinetics: RZOLV

demonstrates dissolution rates comparable to or faster than cyanide during early leach intervals.

demonstrates dissolution rates comparable to or faster than cyanide during early leach intervals. - Higher dissolved gold tenors: RZOLV

achieved consistently higher solution gold concentrations at 48 hours relative to cyanide.

achieved consistently higher solution gold concentrations at 48 hours relative to cyanide. - Scalability confirmed: Laboratory-scale solution tenors are directionally consistent with bulk-scale vat leach solution grades.

- Predictable performance: Results support the use of standard laboratory bottle-roll testing as a reliable predictor of bulk-scale RZOLV

performance.

performance.

While laboratory comparisons are provided for reference only, management notes that the consistency between lab-scale and bulk-scale behavior is a critical indicator of scalable process performance.

Design-Relevant Data Generated for Commercial Evaluation

In addition to metallurgical results, the program generated design-ready data relevant to potential commercial deployment, including:

- Solution flow rates and inventories

- Residence-time distribution

- Reagent management and oxidant demand

- Carbon loading and stripping behavior

- Equipment sizing envelopes

- Preliminary operating cost inputs

These data materially advance RZOLV’s ability to evaluate and design future commercial-scale applications.

Environmental Containment and Closed-Loop Operation

The vat leach test was conducted within a fully contained, closed-loop process circuit, with all process solutions captured, recycled, and managed on-site throughout the program. No process solutions were discharged to surface water or groundwater systems during the test period.

The closed-loop configuration enabled controlled solution management, including consistent pH and oxidation-reduction potential (ORP) control, while minimizing environmental exposure pathways. The chemical system employed does not exhibit the acute toxicity characteristics associated with conventional cyanide-based leaching systems, allowing the test program to be executed under standard industrial handling and containment protocols appropriate for controlled metallurgical testing.

All operational practices were implemented to align with site environmental controls and applicable regulatory requirements, demonstrating the practicality of deploying RZOLV in contained leaching applications where solution stewardship, environmental risk management, and permitting considerations are critical.

in contained leaching applications where solution stewardship, environmental risk management, and permitting considerations are critical.

Conclusions

The bulk-scale vat leach test demonstrates that, under the specific test conditions evaluated, RZOLV’s technology:

- Achieved gold recoveries comparable to cyanide at lab-scale

- Exhibited stable solution chemistry and reagent performance

- Demonstrated compatibility with conventional carbon adsorption and electrowinning circuits

- The RZOLV chemistry showed predictable scale-up behavior relative to prior laboratory testing

- Leached residues exhibited low residual gold content and maintained favorable permeability characteristics throughout the test.

- Doré production and weight were consistent with calculated carbon loadings and overall metallurgical accounting.

- The vat leach test was conducted within a fully contained, closed-loop process circuit, with all process solutions captured, recycled, and managed on-site, resulting in no discharge to surrounding surface water or groundwater systems.

While results are based on a defined bulk sample and operating configuration, the demonstrated stability of RZOLV’s solution chemistry, hydrodynamics, and scale-up behavior indicates that comparable metallurgical performance is reasonably expected across a broad range of oxidized gold materials processed under analogous conditions.

Limitations and Disclaimer

The metallurgical test results reported herein are based on a specific bulk sample and defined test conditions and may not be indicative of performance on other ore types, grades, or operating environments. Comparative cyanidation results were generated at laboratory scale and are provided for reference purposes only. Bulk-scale testing provides indicative data on metallurgical response, solution behavior, and operability; however, additional testing is required to confirm performance consistency and economic applicability at commercial scale. There can be no assurance that results obtained in this test program will be replicated under different conditions or at other sites.

About Rzolv Technologies Inc.

Rzolv Technologies Inc. is a clean-tech company developing innovative, non-toxic solutions that aim to transform gold extraction and mine-site remediation. The Company’s flagship product, RZOLV , is a proprietary water-based hydrometallurgical formula that provides a sustainable, safe alternative to sodium cyanide for the dissolution and recovery of gold.

, is a proprietary water-based hydrometallurgical formula that provides a sustainable, safe alternative to sodium cyanide for the dissolution and recovery of gold.

Cyanide has been the industry standard for more than a century, yet its toxicity has resulted in bans or restrictions across multiple jurisdictions, along with significant permitting, handling, and ESG challenges for mining companies. RZOLV delivers comparable performance and cost metrics to cyanide while offering a non-toxic, reusable, and environmentally sustainable profile, enabling gold extraction in regions, ore types, and project settings where cyanide use is impractical, prohibited, or socially unacceptable. For more information: https://www.rzolv.com.

delivers comparable performance and cost metrics to cyanide while offering a non-toxic, reusable, and environmentally sustainable profile, enabling gold extraction in regions, ore types, and project settings where cyanide use is impractical, prohibited, or socially unacceptable. For more information: https://www.rzolv.com.

Cautionary Note

Neither the TSXV nor its Regulation Services Provider (as that term is defined in policies of the TSXV) accepts responsibility for the adequacy or accuracy of this release.

For further information, please contact:

Contact

Duane Nelson

Email: duane@rzolv.com

Phone: (604) 512-8118

Cautionary Note Regarding Forward-Looking Statements

This news release contains statements that constitute ‘forward-looking statements.’ Such forward looking statements involve known and unknown risks, uncertainties and other factors that may cause the Company’s actual results, performance or achievements, or developments to differ materially from the anticipated results, performance or achievements expressed or implied by such forward-looking statements. Forward-looking statements are statements that are not historical facts and are generally, but not always, identified by the words ‘expects,’ ‘plans,’ ‘anticipates,’ ‘believes,’ ‘intends,’ ‘estimates,’ ‘projects,’ ‘potential’ and similar expressions, or that events or conditions ‘will,’ ‘would,’ ‘may,’ ‘could’ or ‘should’ occur.

Forward-looking information is based on management’s reasonable assumptions, estimates, and expectations as of the date hereof, including assumptions regarding test conditions, material characteristics, operating parameters, regulatory frameworks, and the availability of capital and third-party services. Such information is subject to known and unknown risks, uncertainties, and other factors that may cause actual results or events to differ materially from those expressed or implied, including but not limited to variability in ore characteristics, scale-up risks, changes in regulatory requirements, environmental permitting outcomes, market conditions, and operational execution. Forward-looking information is provided for the purpose of providing information about management’s current expectations and plans and may not be appropriate for other purposes. The Company does not undertake to update any forward-looking information except as required by applicable law.

The forward-looking information in this news release is based on management’s reasonable expectations and assumptions as of the date of this news release.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/279454

News Provided by Newsfile via QuoteMedia